The Silent Struggle: How Supply Chain Leaders Can Rebuild Trust in Technology Before It’s Too Late

Manual processes are silently eroding Europe’s supply chains. Here’s why trust in technology collapsed, how to rebuild it, and what supply chain managers must do now to survive the AI-driven future.

The Invisible Crisis Inside Modern Supply Chains

Across Europe — and indeed, much of the world — a quiet but devastating crisis is unfolding inside supply chains.

Despite decades of technological progress, manual work still dominates the daily operations of many global supply chain teams.

ERP updates, supplier management, shipment tracking, warehouse coordination — still heavily reliant on spreadsheets, emails, and manual entry.

At first glance, this may seem like a matter of operational inertia. But dig deeper, and you’ll find something far more concerning:

A profound loss of trust in technology itself.

In The Silent Crisis in Supply Chain, I explored why the sector — so vital to the global economy — has resisted the very technologies that could unlock its next era of growth.

The problem isn’t just fear of complexity. It’s the cumulative emotional scars left by years of overpromised and underdelivered digital initiatives.

Failed ERP rollouts. Overhyped AI solutions that never worked in real operations. “Digital transformation” projects that drained resources without delivering ROI.

As a result, many Supply Chain Managers, Planners, and Directors have hardened into a protective stance: “We trust what we can control — our manual processes.”

But while they cling to familiar systems, the world is changing around them faster than ever.

Why Manual Processes Are No Longer Sustainable

In Are Supply Chain Managers Ready to Ditch Manual Work for AI?, I wrote that manual chaos is no longer just inefficient — it’s dangerous.

The risks of staying manual are growing:

Slower reaction times: When disruptions hit (like raw material shortages or logistics delays), manual systems can’t adapt fast enough.

Higher operational costs: Manual work requires more human oversight, more corrections, more redundancy.

Data blindness: Without digital systems, supply chains can’t harness real-time insights to predict, optimize, or automate.

Competitive disadvantage: Agile competitors using AI and predictive analytics move faster, cheaper, and smarter.

Supply chain leaders must ask themselves:

Are we operating on tradition — or on strategy?

The world’s best companies aren’t guessing. They’re moving fast, automating aggressively, and re-skilling their people to trust AI-driven systems.

In The Future of Supply Chain: From Manual Chaos to AI-Driven Excellence, I showed how companies making the leap today are laying the groundwork for the next decade of dominance.

Why Trust, Not Technology, Must Be Rebuilt First

The truth is: Digital transformation isn’t primarily a technology project.

It’s a human trust project.

Even the best AI system will fail if the planners entering the data don’t trust the dashboard. Even the most advanced predictive models will be ignored if managers instinctively double-check everything manually.

Rebuilding trust must start with small wins:

Low-risk automations that make everyday tasks easier.

Clear feedback loops where digital tools prove their reliability.

Coaching and mindset shifts around failure, experimentation, and growth.

In The Digital Transformation Playbook: Unlocking Growth in Supply Chain Leadership, I emphasized that digital transformation demands a growth mindset — not just new software.

A Proven Playbook for Managing Energy During Transformation

Most digital transformations fail not because the strategy was wrong — but because leaders burned out before the new habits could take root.

Change is exhausting.

New systems are overwhelming.

Resistance is natural.

That’s why it’s critical for supply chain leaders to manage their energy like a strategic asset during transformation.

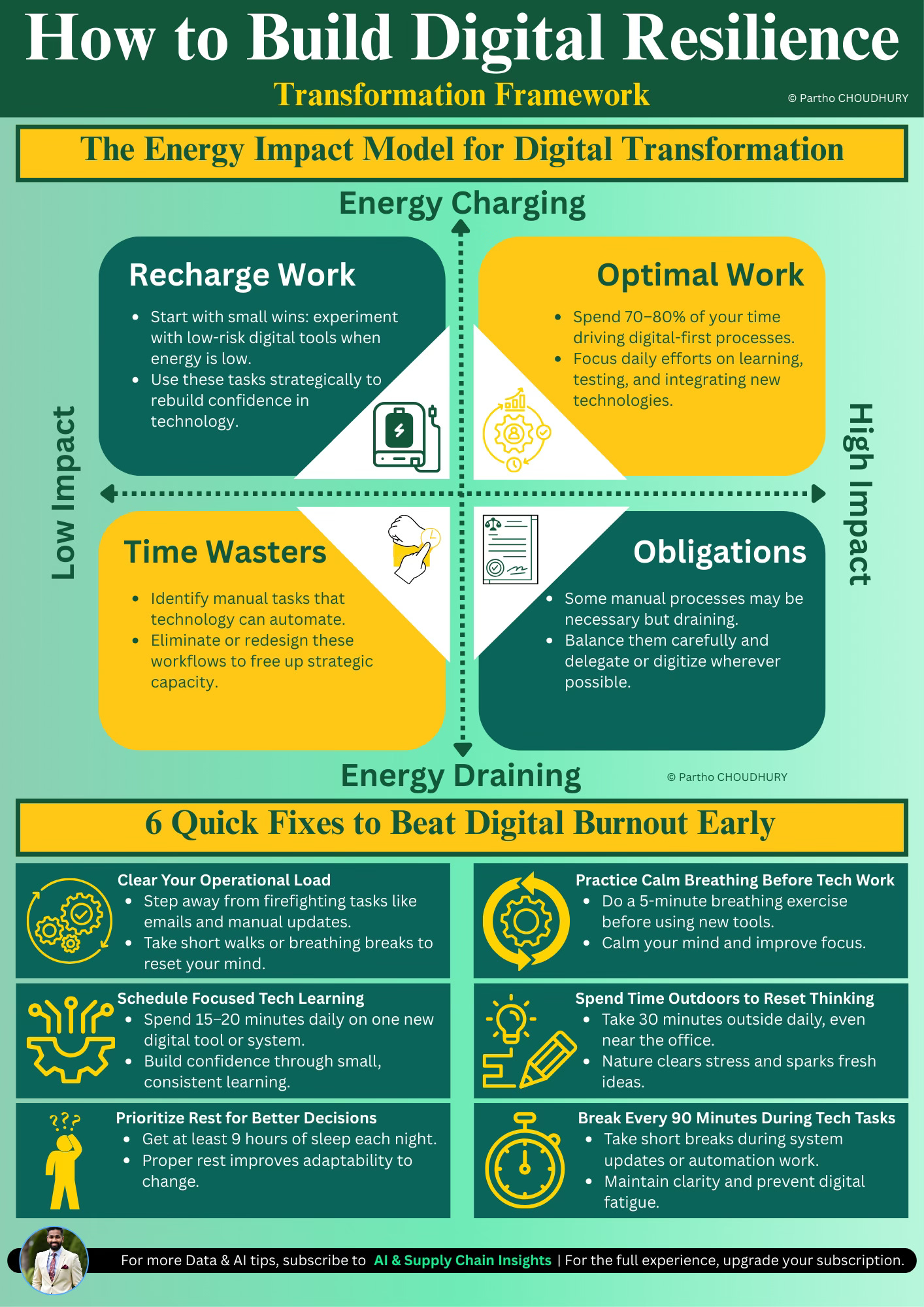

Here’s the adapted Energy Impact Model for Supply Chain Leaders:

Recharge Work

Small, low-risk digital experiments when energy is low.

Rebuild confidence without heavy stakes.

Optimal Work

Spend 70–80% of your time on technology adoption, learning, and process improvements.

Time Wasters

Ruthlessly eliminate redundant manual tasks that slow down innovation.

Obligations

Balance necessary but draining tasks carefully. Delegate or automate where possible.

I expanded on this model in 8 Tech Leadership Strategies to Drive Digital Transformation Success, showing how the best tech leaders protect their teams’ capacity to change.

6 Practical Steps to Embrace Digital Transformation Without Burnout

Here’s a simple but powerful daily operating system for supply chain leaders navigating this journey:

Clear Your Operational Load

Step away from daily firefighting to create mental space for strategic thinking.

Schedule Focused Tech Learning

Spend 15–20 minutes each day learning or practicing a digital tool.

Prioritize Rest for Better Decision-Making

Protect your sleep to stay adaptable, focused, and resilient.

Practice Calm Breathing Before Tech Work

Lower tech anxiety and reset your nervous system before engaging with new platforms.

Spend Time Outdoors to Reset Strategic Thinking

Fresh air boosts creativity, clarity, and resilience — essential for transformation leadership.

Break Every 90 Minutes During Tech Tasks

Short breaks maintain focus, prevent frustration, and accelerate tech mastery.

This isn’t just wellness advice.

It’s performance engineering for change leadership.

Real-World Case Studies: How Leading Companies Rebuilt Trust and Succeeded

If you’re skeptical about whether this playbook really works, look no further than the companies that have already crossed the digital divide:

Spotify: Building a Data-Driven Culture — Scaled experimentation without losing operational discipline.

ING’s Agile Transformation — Rebuilt an entire banking operation to move at tech speed.

AI’s Role in Logistics Transformation — Made smart automation the backbone of supply chains.

1.3 Billion Records: A Global IT Giant’s Reinvention — Cut costs and boosted customer satisfaction through data mastery.

Fashion Retailer: 40% Operational Efficiency Gains — How data strategies deliver measurable ROI.

Merck’s Supply Chain Evolution — Empowered employees to drive AI success from within.

Citizens Bank: From Fragmentation to Focus — Transformed complex legacy systems into strategic assets.

Amazon’s AI Supply Chain Blueprint — Created a model for Europe’s future logistics success.

Ricoh Europe & DHL: Smart Locker Reinvention — Real-world proof that rebuilding trust in tech is possible.

Each case study proves the same truth:

Transformation is a leadership journey, not just a technology upgrade.

The Path Forward: A Call to Courage

The choice facing supply chain leaders today isn’t whether technology will change their world.

It’s whether they will lead that change — or be led by it.

In Are Supply Chain Managers & Planners Ready for the AI Shift?, I challenged leaders to rethink their mental models.

Because the future belongs to those who:

Let go of manual security blankets.

Rebuild trust through small digital wins.

Manage energy strategically.

Lead change with both courage and compassion.

If Europe’s supply chains are to thrive — not merely survive — in the AI era, the transformation must begin within leadership teams themselves.

The next decade will reward not just the fastest movers — but the bravest rebuilders of trust.

The time to start?

Now.

Insightful and practical - thanks! On a related note, regarding AI, it is easy to feel overwhelmed by all the opportunities and the pressure to implement AI. A good tip for some will be to *enjoy* learning about AI and machine learning, rather than just seeing it as something that *must* be learned.

I have worked on two major ERP rollouts for clinical supply (one at Genentech and the other at BeOne (formerly BeiGene), and the automation piece is always partly impacted by Quality Assurance. For biotech and pharma, QA groups might need to see a coordinated industry project that shows absolute transparency of the data, including Regulatory filings and appropriate shelf life data.