Signal Through the Stack

How RFID Optimization at the Pallet Level Unlocks True Visibility in Consumer Packaging

In the race for real-time supply chain visibility, few technologies are as hyped—and as misunderstood—as RFID.

From retail shelves to industrial pallet tracking, the promise is bold: 100% product-level traceability, automated inventory, and minimal human error.

But the real world is noisy. Packaging materials interfere. Stacked pallets distort signals. And tag placement? It’s the difference between seamless scans and total failure.

In this case study, we dive into a hands-on feasibility project conducted by The Axia Institute—where the goal was simple but ambitious:

Achieve 100% RFID readability at the pallet level using only a handheld scanner

🧪 The Challenge

A leading manufacturer sought to integrate UHF RFID tags into their retail and shipping packaging. But their product presented four major hurdles:

Retail items were liquid-filled and wrapped in foil, causing signal interference.

Items were densely packed—up to 40 units per shipping parcel.

Up to 200 parcels were stacked on a single pallet.

The customer required handheld-only scanning, no fixed readers.

In short: high-density, high-interference, high-stakes. Perfect for testing RFID’s limits.

📦 The Testing Framework: From Product to Pallet

The Axia Institute followed a four-phase methodology, using two UHF RAIN RFID tags and 1,440 foil-wrapped retail units. Each phase honed in on a specific packaging level:

Phase 1: Reader Distance at Case-Level

📍 Objective: Determine the optimal scanning distance.

🧪 Result: A consistent readability ratio over four sides of each case, within a fixed 5-second window.

Phase 2: Configuration Within the Case

📦 16 internal item configurations were tested.

🎯 Outcome: Identification of the four highest-performing configurations + optimal reader orientation.

Phase 3: Layer-Level Optimization on the Pallet

📚 Layer-by-layer scan tests revealed how item arrangement impacts readability as cases stack vertically.

💡 Insight: Tag orientation consistency significantly improved read rates across layers.

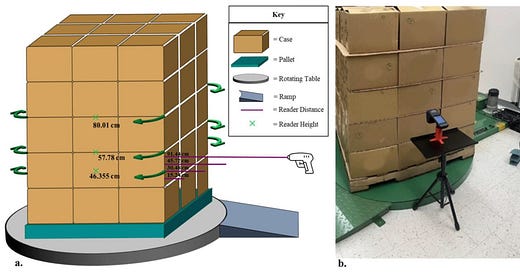

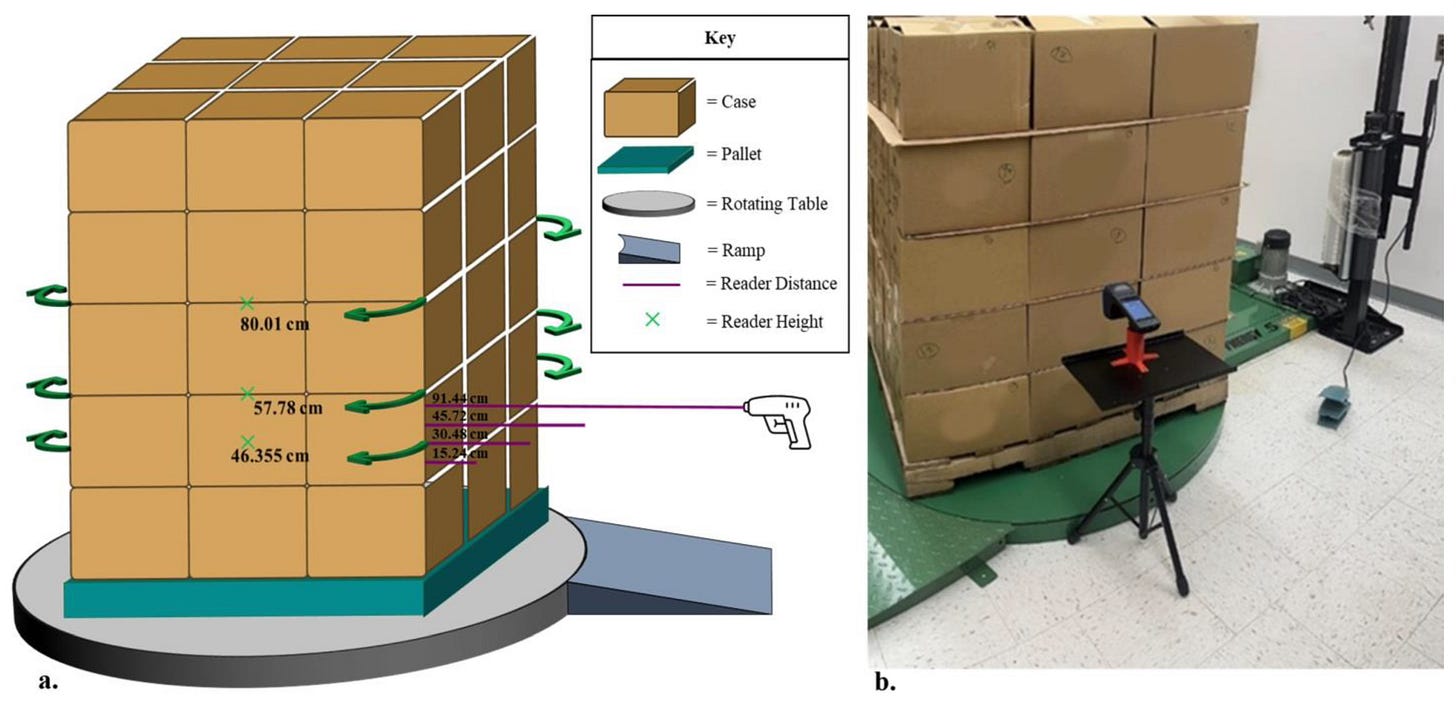

Phase 4: Reader Position at Pallet Level

🎯 Tested five heights and nine distances with a Brady HH-85 handheld scanner.

📈 Each configuration was evaluated over a 60-second scan window.

🔁 A rotating pallet table was tested to simulate motion and improve scan exposure.

📊 The Takeaways

This wasn’t just about hitting a percentage. It was about understanding the physics and logistics behind every scan.

Here are the strategic takeaways:

✅ Tag Design Matters

Even within the same UHF category, tags behave differently depending on the material they’re attached to. Choose based on real-world interaction, not just datasheet specs.

✅ Configuration Is Everything

Tag readability depends as much on how items are packed as on what tag is used.

– Horizontal tags performed better than vertical ones.

– Spacing, symmetry, and edge alignment all influenced signal clarity.

✅ Reader Strategy Can’t Be an Afterthought

Handheld readers demand a smart approach to scanning. Fixed readers are forgiving; handhelds are not.

Scan angles, movement, and orientation consistency all matter.

✅ Dynamic Movement Improves Detection

Adding rotation to the pallet exposed more angles to the handheld reader and increased the overall read ratio—especially for the innermost tags.

🧠 Why This Case Study Matters

As AI and automation accelerate across the supply chain, data integrity starts at the physical layer—and that means packaging.

For companies treating packaging as a post-production afterthought, this case is a wake-up call:

Tag performance is not static; it’s environmental.

Packaging is a strategic data interface, not just a container.

A 99% read rate isn’t good enough if you miss one product in a pallet of 200.

As smart warehouses and predictive logistics become the norm, precision tagging is no longer a luxury—it’s infrastructure.

📦 Bonus Insight: The Hierarchy of Packaging + Data

The case used a three-tiered packaging model that applies broadly across industries:

Primary (Item) – The individual sellable unit. Often where RFID tags are most fragile.

Secondary (Case) – Grouped retail packs. Ideal for intermediate-level scanning.

Tertiary (Pallet) – Bulk configuration that often overwhelms unoptimized systems.

💡 Recommendation:

Invest in visibility from the ground up. Don’t optimize at the pallet until you’ve validated at the case and item levels.

💬 Final Thought

If your supply chain ambition includes real-time tracking, smart inventory, or automation, your RFID strategy must go beyond compliance. It must become a design principle.

The Axia Institute’s work is a rare, transparent look into how technical and physical systems interact—offering not just validation, but a roadmap.

Whether you’re in pharma, retail, food, or manufacturing: RFID isn’t just about tracking. It’s about trust.