Inside Ocado: How AI and Robotics Are Redefining Grocery Fulfillment

From Hive Robots to RaaS: What Supply Chain Leaders Can Learn From Ocado’s Fully Automated Fulfillment Model

Revolutionizing the Future of Grocery Logistics

In the digital age of logistics, where e-commerce speed and accuracy define customer loyalty, Ocado stands out not just as a retailer, but as a technology pioneer. This British online-only supermarket has reimagined the concept of grocery fulfillment, transforming warehouses into intelligent, automated hives where robots and algorithms do the heavy lifting.

As platforms like FreightAmigo push forward the digitization of freight and end-to-end logistics, Ocado’s innovation offers more than inspiration - it offers a glimpse into what the next generation of fulfillment infrastructure could look like across sectors.

🔍 How Ocado’s Automated Fulfillment Center Works

Ocado’s fulfillment centers, dubbed “hives,” are not traditional warehouses. They are data-driven, robot-powered ecosystems engineered for speed, precision, and scalability. Let’s explore the core components:

1. The 3D Grid (“The Hive”)

A multi-story, modular framework where bins holding grocery items are stacked in columns. This cube-like grid is the storage brain.

2. Swarm Robotics on the Grid

Hundreds of autonomous robots race across the top layer at 4 m/s, navigating the hive using AI to pick up bins and transport them to picking stations. Each robot can retrieve any product in under 5 minutes.

3. AI-Driven Traffic Management

A proprietary control system coordinates robot movement in real time, preventing collisions and optimizing delivery paths - essentially air traffic control for bots.

4. Human & Robotic Picking Stations

Bins are delivered to stations where products are packed into orders - either by humans or robotic arms - depending on product complexity.

5. Automated Bagging and Dispatching

After packing, the orders are bagged and sorted into delivery routes, using algorithmic logic to preserve product integrity (e.g. frozen vs. fragile items).

📈 Why Ocado’s Model Is a Game-Changer

✅ Speed & Accuracy

Orders can be fulfilled in 5 minutes - including up to 50 items per order - with an error rate <1%.

✅ Space Efficiency

The vertical, high-density grid model significantly reduces warehouse footprint while increasing SKU storage.

✅ Scalability

Each robot, bin, and grid module can be added independently, enabling on-demand scaling.

✅ Cost Optimization Over Time

Though capital intensive to build, the system dramatically lowers operational costs, labor, and picking errors over time.

🤖 The Rise of Robotics-as-a-Service (RaaS)

While Ocado owns and operates its tech stack, RaaS is rapidly democratizing warehouse robotics. Businesses can now rent advanced robotics solutions on a subscription basis - reducing CapEx and unlocking access to:

AI-driven mobile robots

Autonomous sorting and picking arms

Cloud-based warehouse orchestration platforms

Benefits of RaaS for SMEs and 3PLs:

Low upfront cost, faster ROI

Pay-per-use scalability

Tech updates and maintenance included

Flexible integration with existing systems

RaaS is poised to become the “cloud computing” moment for warehousing: scalable, accessible, and intelligent.

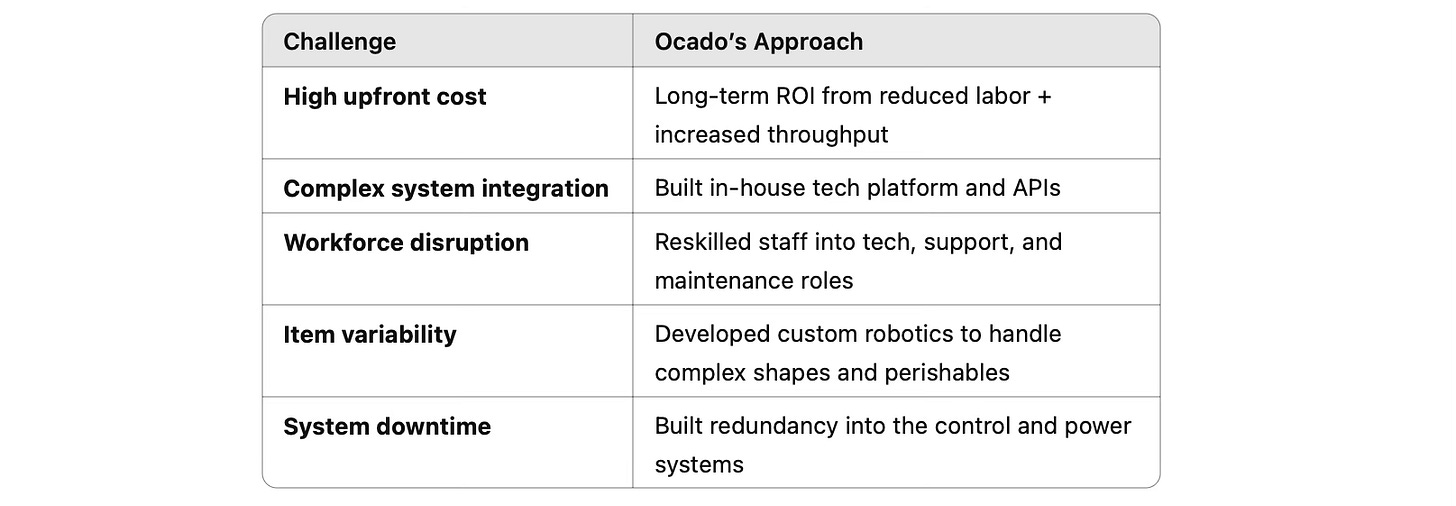

⚠️ Challenges in Automation—and How Ocado Overcame Them

🌍 Industry Impact: Ocado’s Broader Influence

Ocado’s innovations don’t just serve their own operations. They’ve sold their platform to global retailers like Kroger (USA) and Casino (France), and are reshaping expectations in:

Customer Delivery Speed: Same-day or next-day is becoming standard.

Store Formats: Micro-fulfillment centers and dark stores are emerging.

Retail Tech Investment: Legacy retailers are now investing in AI and robotics to keep up.

Data-Driven Supply Chains: Real-time inventory visibility and predictive restocking are becoming a baseline.

🌐 FreightAmigo’s Role in the Automated Fulfillment Ecosystem

Just as Ocado optimizes warehouse operations, FreightAmigo optimizes what happens after the warehouse - from dispatch to international delivery. Here’s how:

🔗 Integrated Freight Booking

Connects directly to sea, air, rail, road freight - matched in real-time to order output.

📦 Automated Documentation

Generates airway bills, commercial invoices, and customs forms with no manual intervention.

📲 Multi-modal Tracking

Connects warehouse automation with last-mile tracking for full visibility across >1,000 carriers.

🔐 Customs Clearance & Cargo Insurance

Seamlessly bundled into the logistics flow, reducing compliance friction.

👨💻 24/7 Expert Support

Automation doesn’t replace human insight - our logistics experts provide fallback support when needed.

🔮 The Future of Fulfillment: 5 Trends to Watch

AI-Powered Predictive Fulfillment

AI models that anticipate orders and pre-stage inventory closer to expected demand zones.

Fully Autonomous Chain

From robot picking to drone delivery or autonomous EV fleets - complete automation is the endgame.

Urban Micro-Fulfillment

Small robotic hubs placed in city centers to meet 1-hour delivery promises.

Robotics in Non-Grocery Sectors

Electronics, apparel, pharma - Ocado-style automation will expand beyond groceries.

Sustainability by Design

Automated systems that optimize packaging, reduce emissions, and minimize food waste.

🏁 Final Thoughts: A Blueprint for the Smart Supply Chain

Ocado didn’t just build a warehouse - they redefined how physical goods are stored, picked, and delivered in the 21st century. For logistics innovators, warehouse operators, and tech-forward retailers, their story is both a benchmark and a call to action.

Platforms like FreightAmigo are building the connective tissue between automated warehouses and global delivery infrastructure. As we bridge robotics with freight, APIs with shipping docks, and AI with real-time data - we’re not just delivering goods, we’re delivering the future.