🔍 Beyond the Manual: How Amazon’s AI-Powered Supply Chain Became the Future Blueprint for Europe’s Struggling Logistics Leaders

✨ Why Supply Chain Professionals Must Finally Trust Tech Again—Before It’s Too Late

📍 Introduction: A Crisis of Trust in Europe’s Supply Chain Nerve Centers

Across Europe, in quiet industrial parks and global trading hubs, Supply Chain Managers, Planners, and Directors still rely on spreadsheets, email threads, and outdated ERP dashboards to manage incredibly complex systems.

Why?

⚠️ Manual operations are no longer just inefficient—they’re unsustainable.

📉 Productivity is stagnant.

📦 Errors are frequent.

⏱️ Speed? Inconsistent.

🌍 Global disruptions? Constant.

Yet amid this friction and fatigue, one company has rewritten the rules: Amazon. And their transformation offers a real-world, working blueprint for Europe’s logistics professionals to trust again—and rebuild smarter.

🧠 Part I: The Trust Gap—Why European Supply Chains Still Resist Digital Transformation

Let’s be honest—AI, digital twins, and autonomous logistics sound great in theory. But for many in operational roles, these concepts are:

• Abstract

• Costly

• And disconnected from the day-to-day chaos of real supply chains

🔎 A warehouse in Rotterdam doesn’t need more dashboards—it needs answers.

🔎 A planner in Munich doesn’t need another system—it needs systems that talk.

🔎 A director in Milan doesn’t need a pilot program—it needs proof of ROI.

For over a decade, “digital transformation” was pushed top-down. It promised automation but delivered complexity. So, trust broke. But what if there was a success story that actually lived up to the hype?

🚀 Part II: Amazon’s AI-Driven Supply Chain—Proof That It Works at Scale

In 2024, Amazon’s supply chain wasn’t just digital—it was intelligent.

Faced with millions of SKUs, global volatility, and sky-high customer expectations, Amazon turned to AI—not as a side tool, but as the core operating system of its logistics.

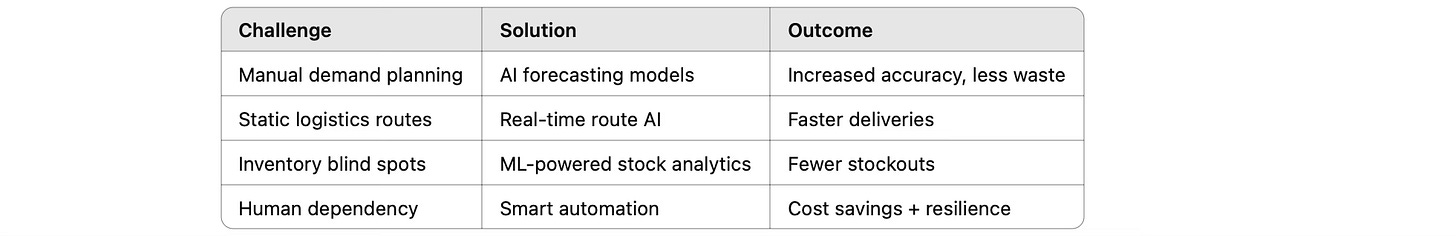

🧭 Challenge #1: Predicting Demand Across the Planet

Amazon needed more than historical averages—it needed hyper-contextual predictions.

✅ Solution: AI-driven demand forecasting that ingests:

• Real-time sales data

• Social trends

• Weather events

• Economic signals

📊 Outcome: When storms are forecast in Paris, local warehouses are auto-stocked with essentials. When social media buzzes about a product in Berlin, inventory is pre-positioned.

No guesswork. Just insight.

Source: Carsten Krause, CDO TIMES Research & Amazon

📦 Challenge #2: Inventory Chaos and Warehouse Inefficiency

Traditional systems couldn’t keep up. Human errors added cost. Replenishment was reactive.

✅ Solution: AI + Robotics + ML

• RPA bots streamline item movement

• ML algorithms optimize reorder points

• Vision systems identify item-level anomalies in real time

🔁 Result: Lower holding costs, fewer stockouts, faster fulfillment—even during crises.

Source: Carsten Krause, CDO TIMES Research & derived from Amazon report

🚚 Challenge #3: Delivery Speed and Logistics Bottlenecks

Legacy routing couldn’t handle dynamic conditions. Congestion, delays, and lost packages were common.

✅ Solution: Real-time AI logistics engine

• Dynamic route optimization

• Load balancing across distribution nodes

• Predictive maintenance for fleet uptime

📈 Impact:

• Delivery times dropped year over year

• Fuel costs fell

• Reliability surged

Amazon didn’t just move faster. It moved smarter.

📉 The Data Speaks for Itself

🔍 “If you can’t measure it, you can’t improve it.” – Peter Drucker

📈 Inventory Turnover Rate (2019–2023)

• ✅ Stable through COVID-19 disruptions

• ✅ Increased efficiency from 2021 onward

• ✅ Reflects success of adaptive AI inventory models

⏱️ Average Delivery Time (2019–2023)

• 📉 Significant reduction post-2020

• 📉 Tied directly to AI route optimization rollouts

• 📉 Correlates with increased Prime renewals

💡 Part III: What European Leaders Can Learn from Amazon’s Transformation

Here’s the hard truth: Amazon didn’t achieve this overnight. It required:

1. Deep investment in clean, structured data

2. Cultural buy-in across departments

3. A willingness to trust the machine—after validating the machine

If Amazon—with its chaos, scale, and complexity—could make AI work, so can others. But it requires rethinking not just tools, but mindsets.

🛠️ Actionable Lessons for Europe’s Supply Chain Pros:

📚 Lessons for Business Leaders — What Amazon’s Supply Chain Reinvention Teaches Us

Amazon’s success isn’t just about scale—it’s about strategy powered by intelligence. Here are key takeaways for leaders ready to future-proof their own supply chains:

💾 1. Invest in Data

📊 “AI is only as smart as the data you feed it.”

Amazon’s AI-driven system thrives because it integrates millions of data points—from sales and social media to weather patterns and global economics.

🔑 Lesson: Build a strong data foundation.

📥 Centralize, clean, and structure data from every touchpoint in your supply chain.

🤖 2. Embrace Automation

⚙️ Automation isn’t about cutting jobs—it’s about freeing humans from repetitive, low-value tasks.

Amazon leverages:

• 🔄 Robotic Process Automation (RPA)

• 🧠 Machine learning to optimize replenishment

• 🚀 Autonomous systems for efficiency

🔑 Lesson: Use automation to enhance human performance, not replace it.

🌪️ 3. Prioritize Flexibility

🌍 The world is unpredictable—pandemics, strikes, geopolitics, weather extremes.

Amazon’s AI systems respond in real time to disruptions, rebalancing logistics dynamically.

🔑 Lesson: Design your operations to adapt and pivot fast. AI makes that possible.

🌱 4. Sustainability Matters

🌡️ Carbon emissions, energy use, and waste are under scrutiny.

Amazon uses AI to:

• ♻️ Optimize routes and reduce fuel use

• 📉 Minimize overproduction and warehousing costs

• 🌍 Align with climate pledges

🔑 Lesson: Sustainability isn’t a side goal—it’s a competitive advantage powered by AI.

💡 Smart supply chains aren’t built overnight—but they begin with bold choices.

Be the leader who chooses to trust technology, elevate your teams, and build for resilience. The future is here—and it’s intelligent.

🧭 Final Thought: It’s Not About Replacing People—It’s About Empowering Them

Let’s clear the air: AI isn’t here to replace supply chain managers.

It’s here to augment them—to free them from the grind so they can lead, think, and innovate.

If Amazon’s case proves anything, it’s this:

🌐 The companies that combine human expertise with machine intelligence will lead the future of global logistics.