Are Supply Chain Managers & Planners Ready for the AI Shift?

Unlock the mental models that the world’s top supply chain leaders are using to navigate the AI revolution — and how you can apply them to stay ahead of the curve.

Brace yourself.

This isn’t just another industry trend. It’s a tectonic shift that’s happening right beneath our feet, and those who ignore it may find themselves left behind. The world of supply chain management is on the cusp of transformation, and the changes will be so profound that businesses that fail to adapt could struggle to recover.

The question is, how will you face this shift?

To answer that, let’s look at how the world’s top supply chain leaders make critical decisions.

These leaders don’t rely on guesswork. They don’t make decisions based on outdated practices or blind faith. Instead, they leverage 5 powerful mental models that guide them through this fast-evolving landscape. These models empower them to make the right calls when faced with uncertainty, and they are a key reason why AI is rapidly becoming their trusted ally.

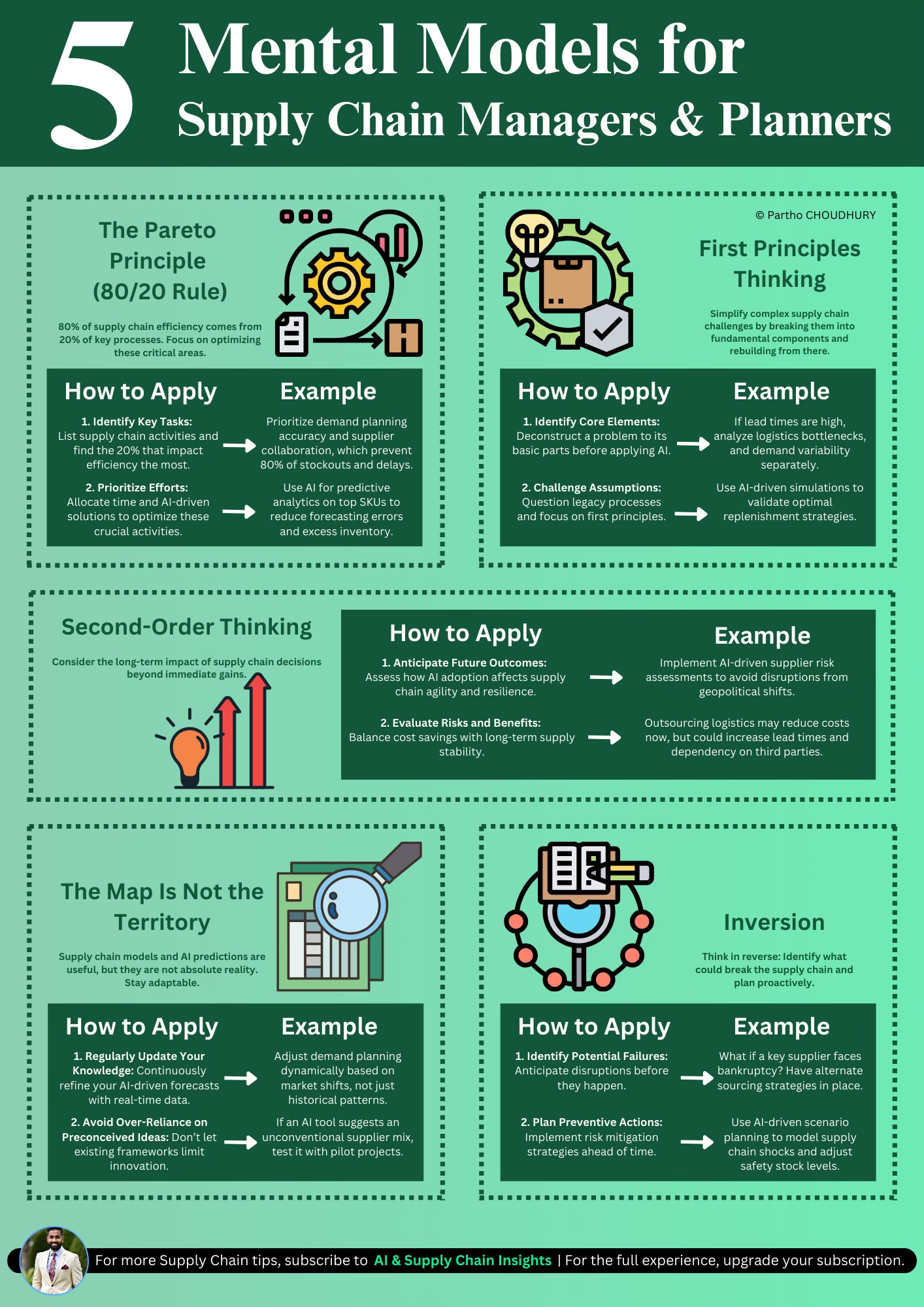

1️⃣ The Pareto Principle (80/20 Rule)

It’s simple, but incredibly powerful.

80% of supply chain disruptions come from just 20% of weak links. Yet, many supply chain planners spend their time trying to optimize everything — chasing after minor inefficiencies while ignoring the major bottlenecks that have the biggest impact on their operations.

The best leaders, however, don’t fall into this trap.

They know the value of focusing on the critical few.

• They identify the 20% of bottlenecks that account for 80% of the delays.

• They invest in predictive analytics to get ahead of the problem before it even occurs.

By applying this principle, top planners focus their efforts where they matter most, reducing disruptions and increasing efficiency. On the flip side, those who ignore this principle waste precious resources, bogged down by unnecessary tasks and missing the big picture.

2️⃣ First Principles Thinking

In a world where AI is rewriting the rules of supply chain management, it’s no longer enough to simply rely on old practices. First Principles Thinking challenges everything we know about supply chains and forces us to rebuild from the ground up.

Instead of relying on assumptions or past solutions, top planners break down complex supply chain challenges to their most basic elements and rebuild the system from scratch.

• What if real-time visibility wasn’t just a dream, but an expectation?

• What if demand planning wasn’t static forecasting, but dynamic, AI-driven adaptation?

The greatest minds in supply chain management aren’t content with just incremental improvements. They see AI as an opportunity to change the game entirely, making supply chains more responsive, more agile, and more efficient than ever before. This shift isn’t in the future — it’s happening right now.

3️⃣ Second-Order Thinking

Every supply chain decision has consequences that go beyond the immediate. This is where the best leaders thrive — by thinking beyond the first-order effects of their decisions and considering what will happen down the line.

For example, lowering costs today might seem like a win, but what happens when that decision disrupts supplier relationships tomorrow? AI-powered logistics may boost efficiency, but will it eliminate the need for human expertise?

The best supply chain managers ask these tough questions before making decisions.

• Will supplier automation kill flexibility?

• Will AI-driven logistics disrupt human expertise?

• Will optimizing one node break the entire system?

Thinking just a step or two ahead can be the difference between thriving in a complex system or being swept away by it. Leaders who engage in second-order thinking create resilient systems that withstand the ripple effects of each decision. Short-sighted leaders, on the other hand, make decisions based on immediate, visible results but fail to consider the long-term consequences.

4️⃣ The Map Is Not the Territory

Too many supply chains still rely on forecasts. But as we all know, forecasts aren’t reality.

• Markets shift.

• Wars erupt.

• Regulations tighten.

Yet, some planners continue to cling to outdated models and rigid assumptions. When external forces disrupt the market, they’re caught off guard, unable to pivot in time to protect their operations.

The best supply chain managers recognize that the map is not the territory. They know that forecasts are just educated guesses and must be regularly challenged and updated.

• They don’t just collect data — they act on it.

• They adapt and update their assumptions daily to keep up with changing realities.

By challenging assumptions, updating data in real time, and adapting to disruptions, top planners can turn uncertainty into opportunity. They thrive in environments of volatility, while others are left scrambling to catch up.

5️⃣ Inversion Thinking

Finally, perhaps the most overlooked but equally essential mental model is Inversion Thinking.

In the quest to optimize and succeed, we often focus on asking, “How do we win?” But the best supply chain leaders go a step further — they ask, “What could cause us to fail?”

• If AI models collapse, what’s the backup plan?

• If geopolitical risks rise, how will we diversify?

• If key suppliers disappear, how fast can we pivot?

Inversion thinking helps supply chain managers design their systems to be resilient — not just efficient. It forces them to plan for the worst-case scenarios so that, when disaster strikes, they are prepared. While others are scrambling to react, those who’ve thought in reverse can execute their contingency plans with confidence.

The Final Question: Will You Adapt Before It’s Too Late?

The AI shift is no longer a distant possibility. It’s already happening, and the question is: Will you be ready? Will you take the time to adopt these powerful mental models and position yourself as a leader in the evolving world of supply chain management?

The choice is yours. The best supply chain leaders are embracing AI as an opportunity to enhance their decision-making, optimize their operations, and create more resilient systems. They are the ones who will lead the charge in the new age of supply chain innovation.

Will you adapt before it’s too late? 🚀

Stay ahead. Adapt. Innovate.

This article was a deep dive into the mental models that are reshaping the world of supply chain management. Stay tuned for more insights on the impact of AI, strategies for adaptation, and how you can stay ahead of the curve.

Feel free to share your thoughts and experiences in the comments below, and if you’re not yet subscribed, don’t miss out on the latest trends in supply chain technology!